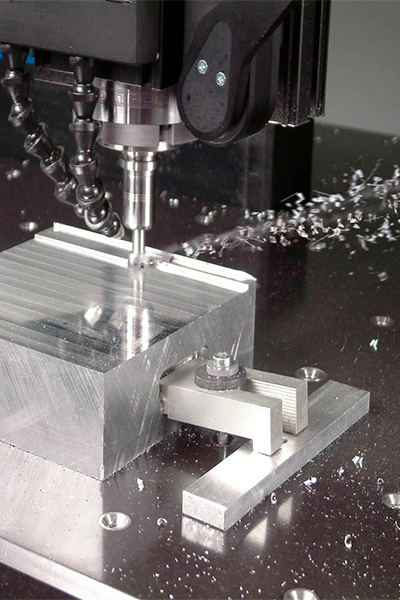

Production of technological equipment

and metal products according to the customer's design documentation

The tooling production is provided by modern machining centers and universal equipment. The polishing base comprises jig grinders, flat surface and circular grinders. Modern electrical discharge equipment and work place for finishing molding tools provide obtaining complex shape items with high accuracy and repeatability. Attainable precision during processing is 7 quality class, roughness is Ra 0.08

A big part of the work shop products is manufactured of tool steel, rapid machining and alloy steel followed by thermal treatment in electric furnace and salt bath (at present modification of the thermal area is taken place). Blank production allows to produce work-blanks using hydro-abrasive and contour band equipment

Related Services

Manufacture of technological

eqipment and metal products

- Molding tools for processing thermoplastic and thermosetting materials, rubber, ceramics;

- Punches (cutting dies, perforating, bending, cupping, sub-press, for die forging cold forming, for chipping printed circuit boards);

- Cutting tools;

- Gages (smooth, planar, threaded gages, complex gages, clamps, special gages);

- Accessories (various workholders, collet chucks, tooling, test and non-standard tool sets)

Equipment maintenance and repair

- We carry out consultations on questions of equipment maintenance service;

- We develop and implement maintenance programs according to your operating conditions;

- We carry out repair of separate blocks and knots of the equipment;

- We offer the necessary consumables for maintenance and repair of equipment;

- We carry out modernization of the equipment